The Power of Point To Point Diagnostics in Dryer Heating Circuits

Diagnosing issues in dryer heating circuits can be challenging due to their complex electrical pathways. A systematic approach, such as point-to-point voltage drop testing, is essential for accurate troubleshooting. This method involves sequentially measuring voltage drops across components to pinpoint faults effectively.

Understanding Point-to-Point Diagnostics

Point-to-point diagnostics entail measuring voltage at specific points along a circuit to identify discrepancies indicating faults. This technique is particularly useful in 240V appliances like electric dryers, where heating elements may not receive proper voltage due to issues such as faulty connections or component failures.

Application in Dryer Heating Circuits

In electric dryers, the heating element operates on a 240V circuit, while controls and motors typically use 120V circuits. When the dryer fails to produce heat, the issue often lies within the 240V heating circuit. By employing point-to-point voltage drop testing, technicians can systematically assess each component—thermal fuses, thermostats, heating elements, and connections—to locate the exact point of failure.

Advantages of Point-to-Point Voltage Drop Testing

-Precision: This method allows for accurate identification of faulty components, reducing guesswork and unnecessary replacements.

-Efficiency: Systematic testing streamlines the diagnostic process, saving time and resources.

-Safety: Identifying issues such as compromised voltage sources or loose connections enhances the safety of both the technician and the appliance user.

Implementing the Technique

To perform point-to-point voltage drop testing:

1. Safety First: Ensure the dryer is disconnected from power before beginning any diagnostic procedures.

2. Access the Circuitry: Open the dryer's access panel to reach the heating circuit components.

3. Sequential Testing: Using a multimeter set to the appropriate voltage range, measure the voltage drop across each component in the heating circuit.

4. Analyze Readings: Compare the measured values against standard operating voltages to identify anomalies indicating faulty components.

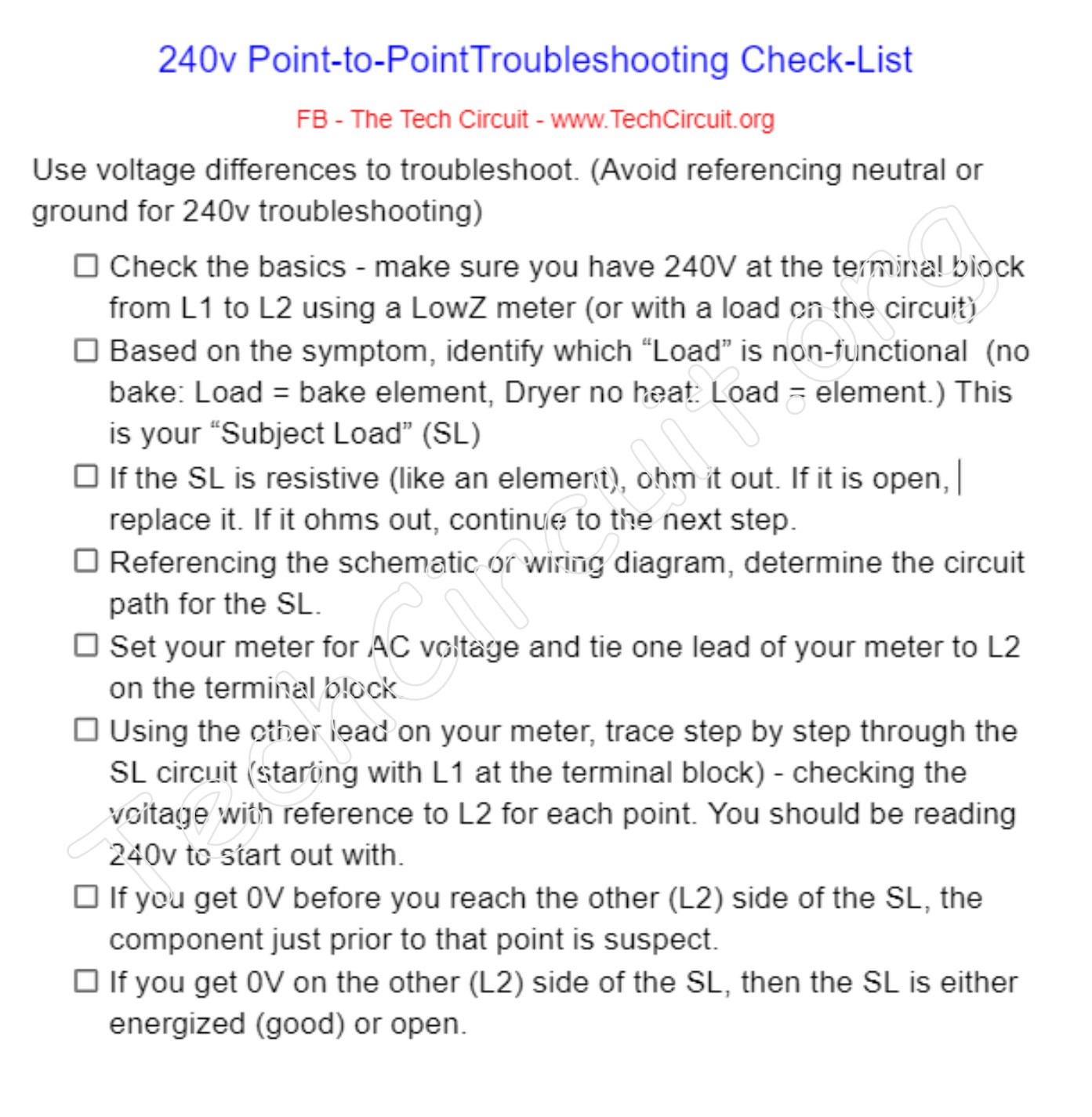

For a comprehensive guide on 240V point-to-point troubleshooting, refer to The Tech Circuit's 240V Troubleshooting Cheat Sheet

Conclusion

Mastering point-to-point diagnostics is crucial for effectively troubleshooting dryer heating circuits. This method enhances diagnostic accuracy, promotes safety, and improves repair efficiency. Technicians seeking to deepen their understanding of appliance circuits and diagnostics can find valuable resources at The Tech Circuit.

The Tech Circuit™

By adopting systematic voltage drop testing, professionals can ensure reliable dryer repairs, leading to increased customer satisfaction and appliance longevity.