How do Gas Dryer Ignition Circuits Typically Work?

Gas dryers are essential appliances in many households, efficiently drying clothes by combining heat and tumbling action. A critical component of their operation is the gas ignition circuit, which ensures the safe and effective ignition of gas to produce heat.

Components of the Gas Ignition Circuit:

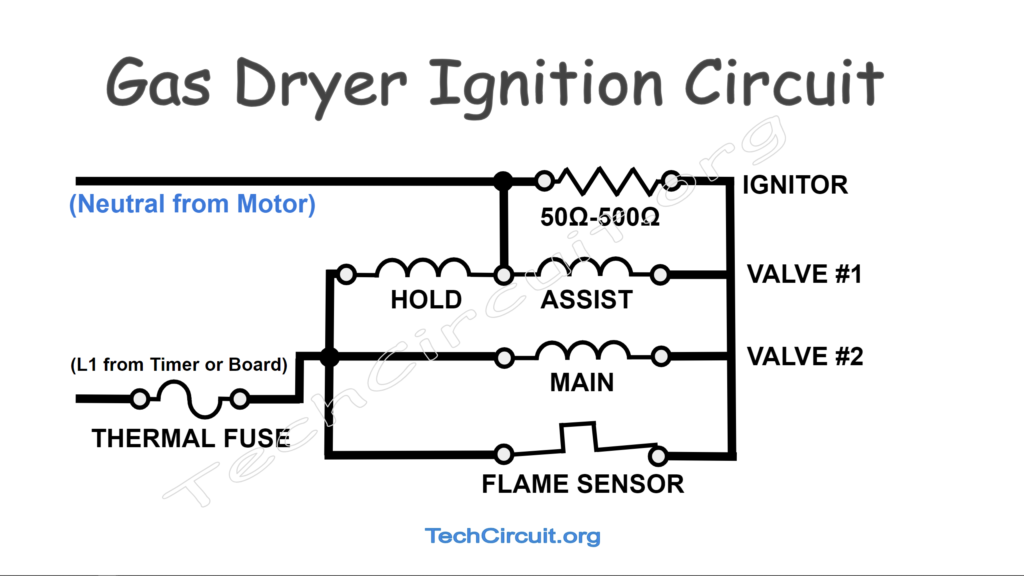

1. Ignitor: This device heats up to a high temperature, becoming hot enough to ignite the gas. It typically has a lower impedance (50–500 ohms) compared to other components.

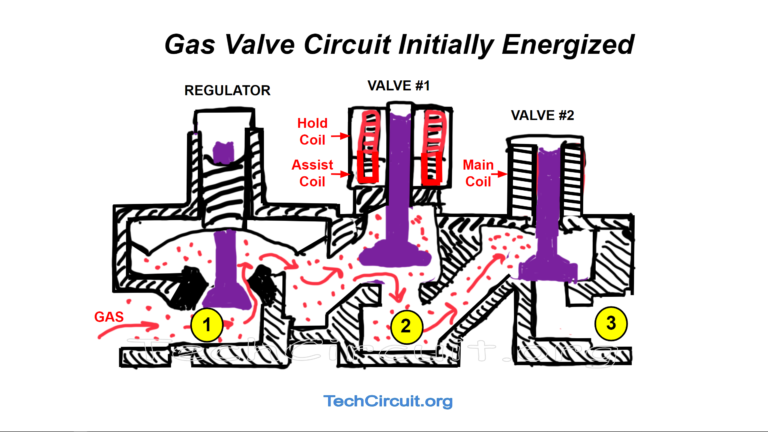

2. Gas Valve Coils (Solenoids): These electromagnetic coils control the opening and closing of gas valves. Commonly, there are three coils: the hold coil, assist coil, and main coil, each with an impedance ranging from 500 to 2000 ohms.

3. Flame Sensor (Radiant Sensor): Initially closed, this sensor monitors the presence of a flame. Upon detecting sufficient radiant heat, it opens to indicate successful ignition. This in turn, prompts the gas valve assembly to open and allow ignited gas to flow.

Operational Sequence:

1. Initial State: When the dryer starts, the timer or control board supplies 120V to the ignition circuit through thermal devices, reaching the flame sensor. However, without the motor running, the centrifugal switch remains open, preventing neutral from completing the circuit. Consequently, no current flows through the ignitor or coils at this stage.

2. Ignitor Activation: Once the motor reaches the required RPM, the centrifugal switch closes, introducing neutral to the ignitor. With the flame sensor still closed, a 120V potential difference appears across the ignitor, causing it to heat up and glow. Simultaneously, the hold and assist coils receive voltage, opening Valve #1 and allowing gas to flow into the first section of the gas valve assembly. The main coil remains unenergized at this point, preventing full gas flow.

3. Flame Sensor Response: As the ignitor heats up, the flame sensor detects the radiant heat and opens. This action redirects current through the main coil, energizing it and opening Valve #2. With both valves open, gas flows through the assembly and is ignited by the hot ignitor, producing the flame necessary for drying.

4. Maintaining the Flame: The ignitor then deactivates, but the flame sensor ensures the gas valves remain open as long as the flame persists. If the flame extinguishes unexpectedly, the sensor detects the temperature drop, causing the gas valves to close as a safety measure.

Common Issues and Troubleshooting:

1. Faulty Ignitor: If the ignitor doesn't glow, it may be defective. Testing for continuity can confirm its condition.

2. Defective Coils: Worn or damaged coils may prevent the gas valves from opening. Inspecting and replacing faulty coils can resolve this issue.

3. Malfunctioning Flame Sensor: A sensor stuck in the closed position can hinder proper ignition. Testing its functionality and replacing it if necessary is advisable.

Understanding the gas ignition circuit's operation is vital for diagnosing and repairing gas dryer issues. Regular maintenance and prompt attention to malfunctioning components can ensure the dryer operates safely and efficiently.

For a visual demonstration of ignitor testing and troubleshooting, you may find the following video helpful: https://youtu.be/2_WW09NdXso